CLAAS LEXION delivers performance like never before with improved precision, efficiency, comfort & reliability.

- NEW cab – noticeably more spacious at head, leg and shoulder level and features a completely new air conditioning concept

- NEW discharge pivoting spout – easily adjustable via CMOTION multifunction lever for precise control

- NEW 12″ CEBIS touchscreen display – improves user-friendliness and provides intelligent operator assistance

- NEW 16.2L MAN D42 engine for LEXION 8800 TERRA TRAC now boasts 700hp

- NEW grain tank options up to 18,000L

We are now taking orders for delivery in 2025. Don’t delay, secure your new LEXION for next year’s harvest.

DISCO

Disc mowers

CLAAS DISCO front, rear, trailed and combination mowers are designed to withstand maximum loads while consistently delivering a top-quality cutting result.

- Top chop quality with the MAX CUT mower bar on most models

- Perfect cut and smooth running, even at high speeds

- Innovative bolt concept for maximum deflection and impact resistance, even under extreme loads

- Low diesel consumption, thanks to ACTIVE FLOAT and the economy PTO (850 rpm)

- SAFETY LINK reliably protects the drive train, and is quickly replaced when required

VOLTO

Tedders

CLAAS delivers modern technology in working widths of 4.5 to 13m with trailed or three-point linkage attachments.

- MAX SPREAD crop flow - clean, even spread at high working speeds

- Maintenance-free power transmission with PERMALINK finger clutch

- Comfort on the job thanks to CLAAS power drawbar

- Dependable ground tracking, with additional guide wheel

- MAX SPREAD equipped with a hermetically sealed, continuously lubricated rotor transmission

Liner

rakes

Choose from the wide range of single, twin or quad rotor CLAAS LINER swathers that meet your needs in terms of working width, transport height, ground contour following and, ultimately, feed quality.

- Continuously lubricated and hermetically sealed swathing drive

- PROFIX tine arm bracket ensures secure, play-free attachment and easy tine arm replacement

- Fully floating suspension provides three-dimensional ground-contour following

- Transport height below 4 m without removing individual tine arms

ROLLANT

Round baler

With four models in the ROLLANT range, CLAAS has put forward a powerful team which combines outstanding productivity, an ease of operation and maximum reliability.

- Bale size 1.25 - 1.35 x 1.20 m

- 2.10 pick up - 25 knives

- Wrapping process accelerated by over 30% - just 23 seconds for six layers of film

- Steel-roller rolling chamber with hydraulic MPS PLUS

- ISOBUS control and monitoring via CLAAS COMMUNICATOR II

VARIANT

Round baler

This outstanding performer now features a reworked 360 degree rotor for RC machines, smarter shaped bales with the new patented CLAAS wrapping system, and improved convenience for the operator.

- ROTO CUT: new 360 degree cutting rotor with 14 blades

- Heavy Duty: reinforced chains, knife protection and an extremely robust rotor

- ROTO FEED: spiral rotor for uniform crop flow

- Variable bale diameter of 0.9m to 1.8m, discharging within six seconds

- 2.10 m (or 2.35 m) pick up, suitable for silage, hay or straw

QUADRANT

Square baler

Our sturdy and reliable QUADRANT square balers will help you get the job done well, with their outstanding throughput, superior bale density and excellent chop quality.

- Optional hydraulic driven pick-up with speed adjustment and reverse options

- Suspended pick-up guide wheels for optimal ground-contour following

- Patented roller crop press for accelerating the crop flow in all QUADRANT models

- Pick-up with PFS (Power Feed System) for rapid transfer of the crop to the rotor for high throughput

- Active feed rake - even filling of the chamber for all crop types: the CLAAS crop flow concept

- Perfect bale shape with a consistent density: the hydraulic packer tine control is impressive whatever the condition

CARGOS

Dual-purpose wagons

With the CARGOS 8000, you can be more productive than ever before - the CARGOS can be easily converted from a loading wagon to a sturdy forage transport wagon in no time.

- Solid construction provides the required stability in the field

- Hydraulically driven pick-up is controlled on both sides and features a 2 m working width and five rows of tines

- The complete loading and cutting assembly is easily removed or installed in about 20 minutes

- The EFS (Efficient Feeding System) crop flow concept is the perfect partner for green forage harvesting

- A low-positioned rotor, with nine rows of helix arranged tines and 22 mm conveying fins, guarantees optimum chop quality and transports the forage gently

SCORPRION

Telehandler

New this season, the SCORPION has a powerful, continuously variable drive train, outstanding maneuverability and many automatic functions to help you carry out loading operations safely, conveniently and above all, quickly.

- Choice of two electronically-activated ground drive systems up to 40 km/h

- Deutz high-torque 4 cylinder high-performance engines up to 136 hp

- Improved SMART ROADING for optimised engine control and reduced fuel consumption

- Load-sensing system with pump capacity of up to 160 l/min

- SMART LOADING bundles and a suite of machine optimisation systems for precise control

- New ergonomic, spacious cab and a perfect all-round view

LEXION

Combine harvestors

When real-world requirements and experiences are combined with the latest research findings, the result is a machine which impresses on every count.

- Unique CLAAS HYBRID (APS + ROTO PLUS) threshing and separation technology

- CLAAS TERRA TRAC tracked assembly (635 mm or 890 mm) with hydro pneumatic suspension

- GRAIN QUALITY CAMERA for automatic monitoring of grain quality

- Smart on-baord technology - CEBIS, CEMOS, CEMOS AUTOMATIC, CRUISE PILOT, automatic guidance and TELEMATICS ensure outstandingly convenient control and easy monitoring

- Mercedes-Benz OM 473 LA, Perkins 2206F and Mercedez-Benz OM 470 LA engines offers reliable power reserves

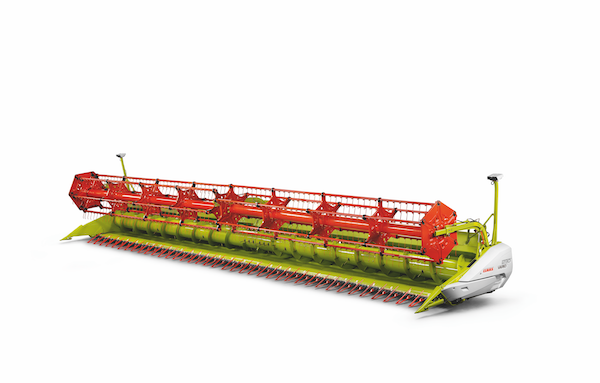

VARIO

Cutterbars

VARIO cutterbars from CLAAS are synonymous with the best cutterbar table adjustment system in the market, designed for the most demanding field conditions.

- Integrated rapeseed plates allow infinite adjustment within an overall range of 700 mm for grain and rapeseed

- Large, 660 mm diameter intake auger for optimal crop flow

- Reel optimised to reduce stalk take-up

- MULTIFINGER intake auger

- Quick-release mounting system allows crop dividers and rapeseed knives to be fitted/removed without the need for tools

JAGUAR 800 Series

Forage harvesters

More productivity, more choice, more comfort, more yield: the JAGUAR 800 and 900 series offer all these qualities and set themselves in a class of their own.

- High operating comfort with operator assistance systems

- Optimal crop flow - consistent chop quality, low diesel consumption and high throughput

- V - Classic cutting cylinder and crop processing to meet every requirement

JAGUAR 900 Series

Forage harvesters

Both utilise CLAAS Power Systems, high performance yet economical engines from 428 to 884 hp. They use a straightforward, highly efficient drive system, and CEBIS technology for compact and user-friendly operator control.

- High operating comfort with operator assistance systems - Cruise PILOT, Cam PILOT, dynamic power, AUTOFILL

- COMFORT CUT infinitely variable chop length adjustment - V - Max chopping cylinder for unrivalled chopping quality

- Efficient ground drive system for increased traction and fuel economy including optional front axle diff lock

SHREDLAGE

Maize processor

MCC SHREDLAGE rollers more effectively process maize crops, intensively processing the forage making the nutritional content higher quality and more readily available in long-chop maize silage, for use in high-ratio diets.

MCC SHREDLAGE rollers are used in combination with V20 or V24 choppers to intensively process kernels and long chop silage (up to 30 mm). The 250 mm diameter MCC-LARGE rollers have 110 and 145 teeth respectively, while the 196 mm diameter MCC-MEDIUM rollers have 100 and 125 teeth respectively. The teeth are set in a sawtooth profile and with an opposing spiral groove. The rollers operate on a 50 percent speed differential.